overview

essence casting electromagnetic stirring that by means of the electromagnetic force generated by the electromagnetic stirring effect to strengthen steel slab of uncured liquid movement, thereby changing the course of the solidification of liquid steel flow, heat transfer and migration, to improve slab quality purpose.

practice and a large number of metallurgical industrial operation proves that the caster reasonable electromagnetic stirring can effectively improve the internal organizational structure of the slab, improve surface quality and reduce center segregation and center porosity, eliminate shrinkage and cracking center, greatly increasing the equiaxed rate. at the same time casting process conditions can be relaxed to increase the casting speed.

electromagnetic stirring action is not a panacea, its metallurgical results and bad casting process conditions have a great relationship. therefore, the control should be related to the metallurgical quality or the caster's own process metallurgy and metallurgical theory to consider, electromagnetic stirring process measures can be relaxed to such requirements, but can not replace.

a complete set of continuous casting electromagnetic stirring device consists of five parts:

◆ power supply part (including high and low voltage transformer and power distribution) (share a)

◆ high-power inverter (one per stream)

◆ electromagnetic stirrer (stirring coil) (one per stream)

◆ cooling water system (a common)

◆ monitoring and operating the computer (ipc) (a share)

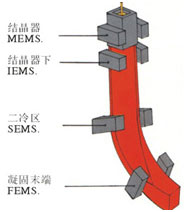

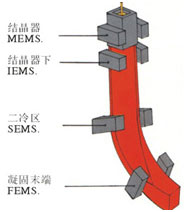

installation location

can be installed in any location throughout the metallurgical length of the caster electromagnetic stirrer in principle, reasonable installation position not only to obtain good metallurgical results it is crucial, but also indirectly related to the running costs of the system.

◆ mold electromagnetic stirrer (mems)

◆ secondary cooling zone electromagnetic stirrer (sems)

◆ solidification and electromagnetic stirrer (fems)