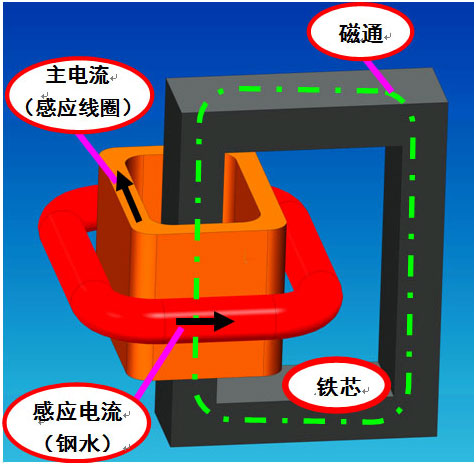

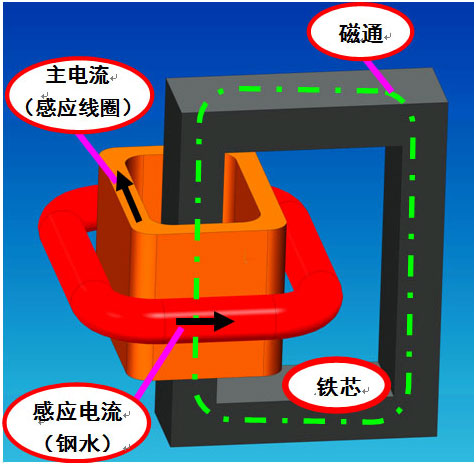

tundish channel electromagnetic induction heating working principle is based on the principle of electromagnetic induction, when the inductor current is fed to an intermediate frequency, alternating current to establish the main magnetic flux φ in the closed magnetic circuit core, the alternating magnetic flux φ on in turn the core strand with the flow channel in the molten steel from the electric potential induced in e, since the molten steel flowing through the inner passage having a conductive, thereby forming an induced current therein, a large circulation current produces joule heat induced in the molten steel in order to achieve steel thermal insulation and heating effect.

and the heating effect is accompanied by raw refining effect of molten steel. the mechanism, one of the induced current in the channel with its own magnetic field induced excitation of the interaction force pinch point center of the channel, pinch force is a volume force acting on the volume element in the molten steel, the molten steel nominal density increased, leading to and the inclusion of the density difference increases, so that the light phase inclusions easily be absorbed by the walls of the channel mobility channel wall removed; the second is the flow of molten steel is heated by the pinch force propelled by the channel to accelerate the discharge port upwelling formed to promote inclusion floating to the free surface coating agent is absorbed and removed; while also promoting the upwelling of molten steel in tundish mixing of hot and cold its temperature distribution.