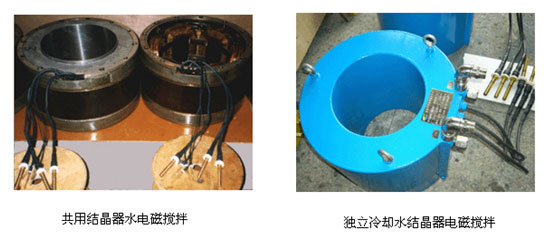

prior to 2004, whether foreign or domestic manufacturers to produce the electromagnetic stirring of the built-in magnetic stirrer adopt a common mold water cooling coil mode, electromagnetic stirrer structured in this manner the presence of ordinary life is not long case or as long as eight or nine months, as short as only one or two months, seriously affected the normal production of steel, so steel mills have to increase the number of spare parts to improve costs, some mills once discontinued. during this period there are many manufacturers in the electromagnetic stirring coil electromagnetic stirring process fuss, increasing life expectancy is limited, i have been trying to find out the improved method, the end of 2003, we have provided an electromagnetic stirrer three products shougang steelworks technical staff recommended that if we could share a built-in water mold electromagnetic stirring without changing the crystalline structure of the premise of the continuous casting machine # 4 made in the form of independent water supply. after months of work, in may 2004 i trial for two separate cooling water built-in magnetic stirrer shougang 4 # caster trial. after six months of use, the test coil insulation resistance significantly improved compared with the original common crystal water coil, the coil out of the water temperature is only 2-3 ℃ cooling effect is quite good, life has been significantly improved (increased from a few months up to a year or more), for acceptance by the parties after the application for a patent (patent number: zl200420048805.5).

then in january 2005, the other six all into this flow configuration mode, and increase independent closed-loop water system set of eight streams. then i will continue to spread this patented technology products, has in shougang, jiyuan iron and steel company, northern taiwan iron and steel company, shaoguan steel, lingyuan iron and steel company, changzhou zhongtian iron and steel company, huaxi village iron and steel company, xuanhua steel and chengde steel the company, hanyang iron and steel company, shougang qian'an iron and steel group company, dozens of electromagnetic stirring steel company won the bid, greatly reducing the maintenance costs of steel, such a small built-in patent avoid electromagnetic stirring were eliminated fate, creating a built-in electromagnetic stirring of a new era for china's steel industry has made tremendous economic benefits.