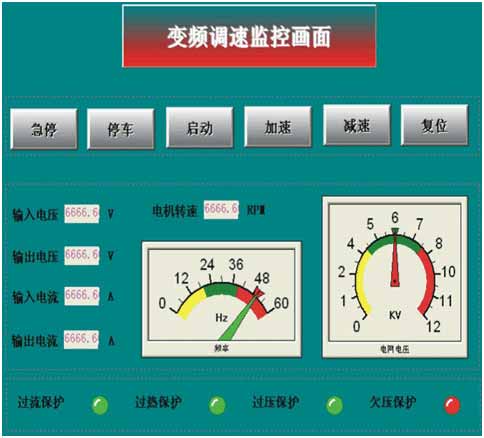

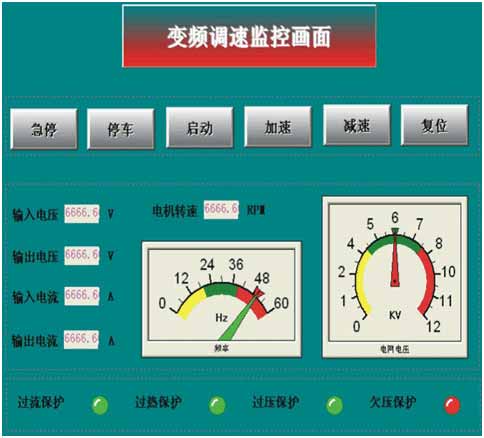

★ protection: power section overcurrent, overheating protection, input over and undervoltage protection.

★ redundancy features: standard mo series buckle achieve high voltage output, improved redundancy and reliability of the drive.

★ current limit function: to set the current limit on the control, avoid starting or load change inverter output current is too large to protection action.

★ control interface function: no 0-10v / 4-20ma analog input and output signal interface, digital input and output interface and a bus interface, the bus interface can be selected on-site and remote control mode.

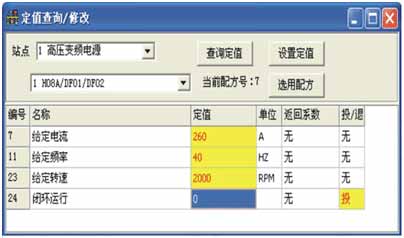

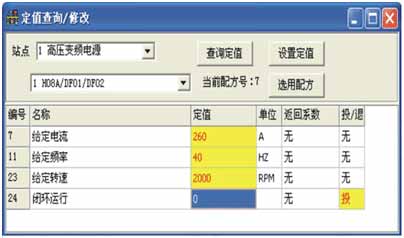

★ parameter setting function: to facilitate the whole chinese windows interface, the drive parameter setting, run the report can be printed. nowhere can depending on the application, set the v / f control curve.

★ waveform display function: the inverter output voltage, output current, the transformer primary voltage, the primary current.

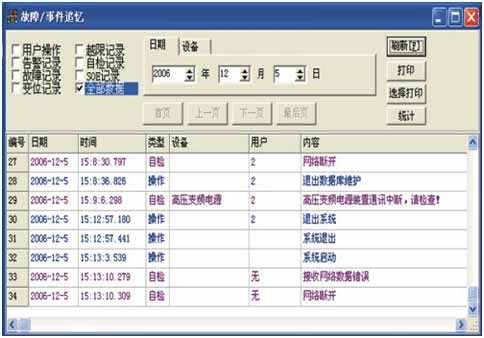

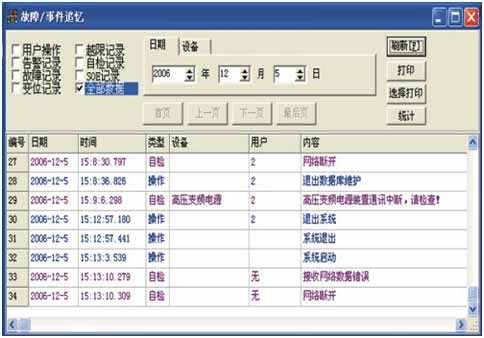

★ fault inquiry function: high-voltage inverter with fault location and query functions. in any case, the user can be informed through the fault query window system time of the current situation and the previous failure has occurred occurred because of the location, in order to take appropriate action.

★ avoid frequency function: frequency inverter has five escape area, the unit can avoid the resonance point or fan rate surging area.

★ motor soft start function: to ensure a smooth start motor, start and stop time in 2-2000 seconds continuously adjustable.

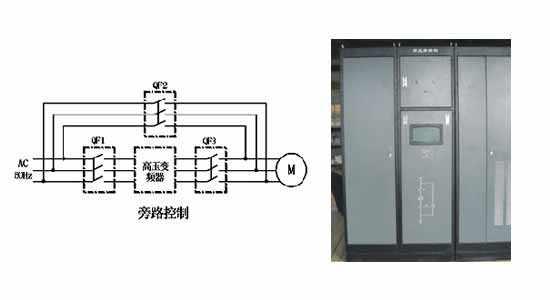

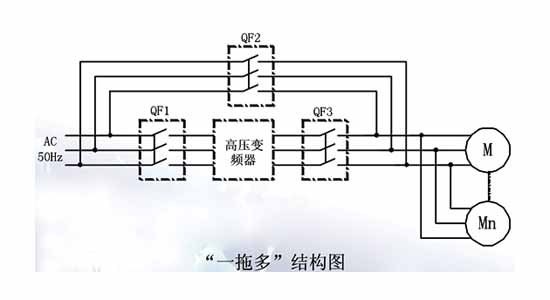

bypass function:

high-voltage inverter is equipped with a bypass switch cabinet, the bypass cabinet and sub-cabinet two automatic manual bypass.

manual bypass: when the high-voltage inverter fault maintenance state, you can bypass cabinet qf1 and qf3 off, and then close the qf2, isolating the high voltage inverter, which does not affect the running load.

automatic bypass: high-voltage inverter can achieve soft-start normal state of operation and frequency inverter operation amounts to switch between functions; automatic fault bypass state inverter, inverter repair and maintenance by-pass switch cabinet manual gear enabling the load from the motor stops to meet some users' uninterruptible power load requirements.

"a drag n function"

as shown, in the power, voltage and other parameters to match the conditions of high-voltage inverter simultaneously with more than one motor frequency operation, while controlling multiple motors start and stop.

operation mode setting function

open-loop control: running frequency is set by the user directly given

closed-loop control: built-in pid controller according to the user to set a target value (pressure, temperature, etc.) and automatically adjust the inverter output.

vector control: starting torque, fast dynamic response, stability control, high precision.